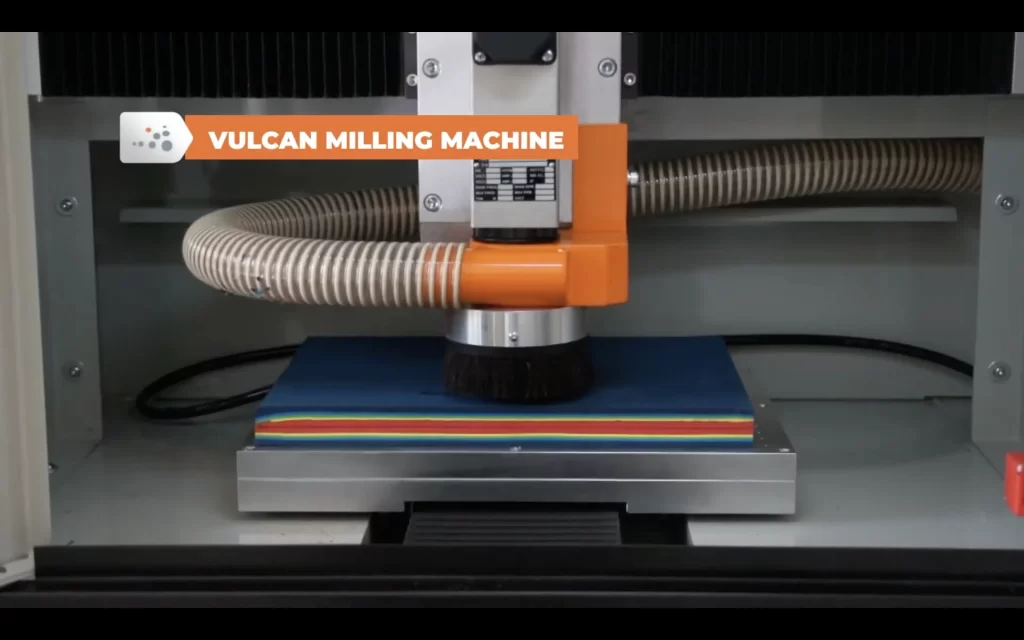

Vulcan CNC

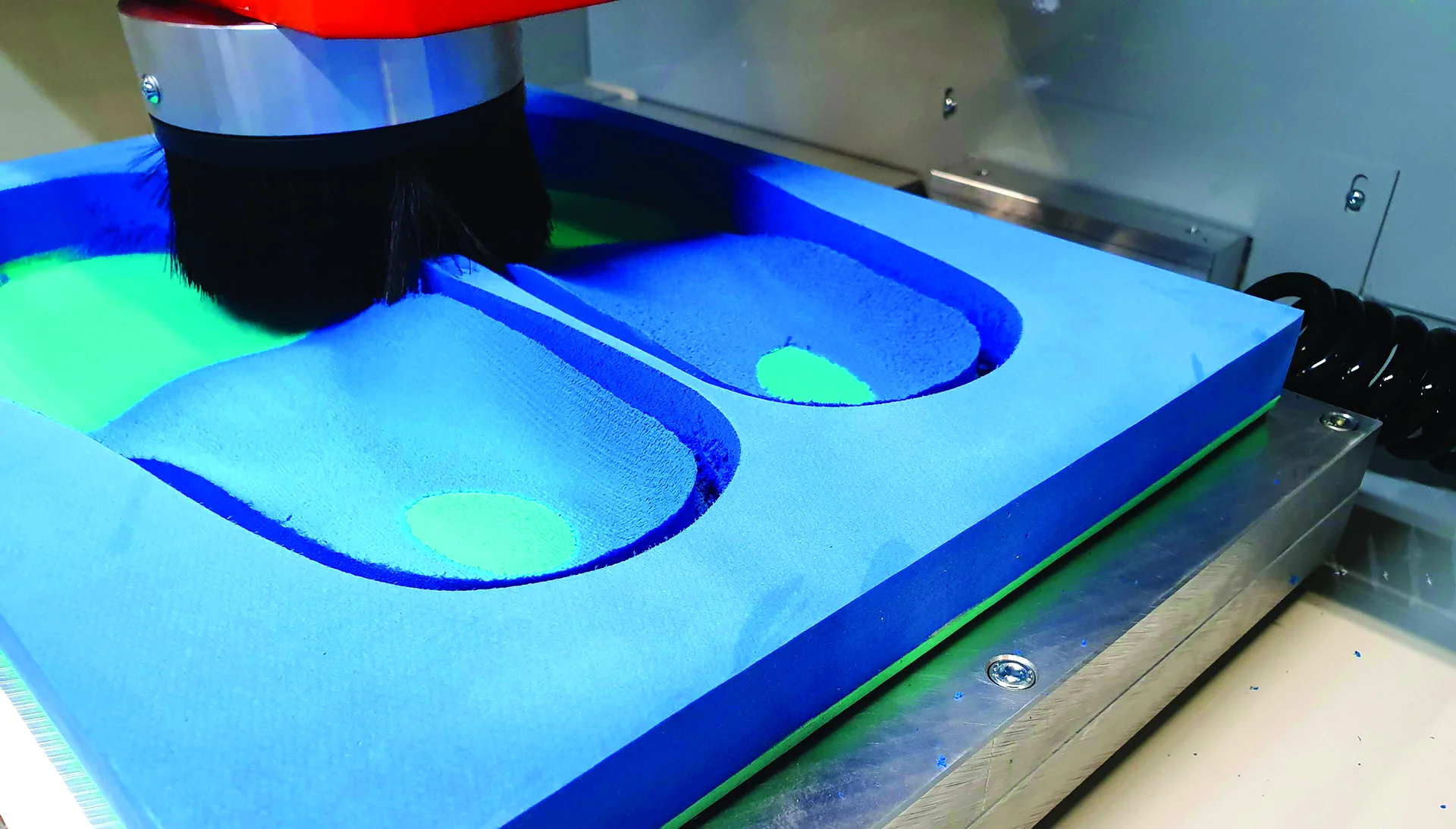

Numerical Control Mills for the production of orthotic insoles. The work centers of the Vulcan series are professional numerical control machines specially designed for the production of customized and pre-finished orthotic insoles. Vulcan cutters are designed for high workloads and are sized for particularly high operating speeds on the supports.

Vulcan Series

VULCAN VX1

3-axis numerically controlled milling machine with single electrospindle. Time needed to create a pair of orthotic insoles: 12 minutes.

VULCAN VX1 REPLICA

3-axis numerically controlled milling machine with single electrospindle. Time needed to create a pair of orthotic insoles: 7 minutes.

VULCAN TWINCAM

The only milling machine of its kind in the world with 4 independent axes and 2 electrospindles. Time needed to create a pair of orthotic insoles: 4 minutes.

Photo gallery

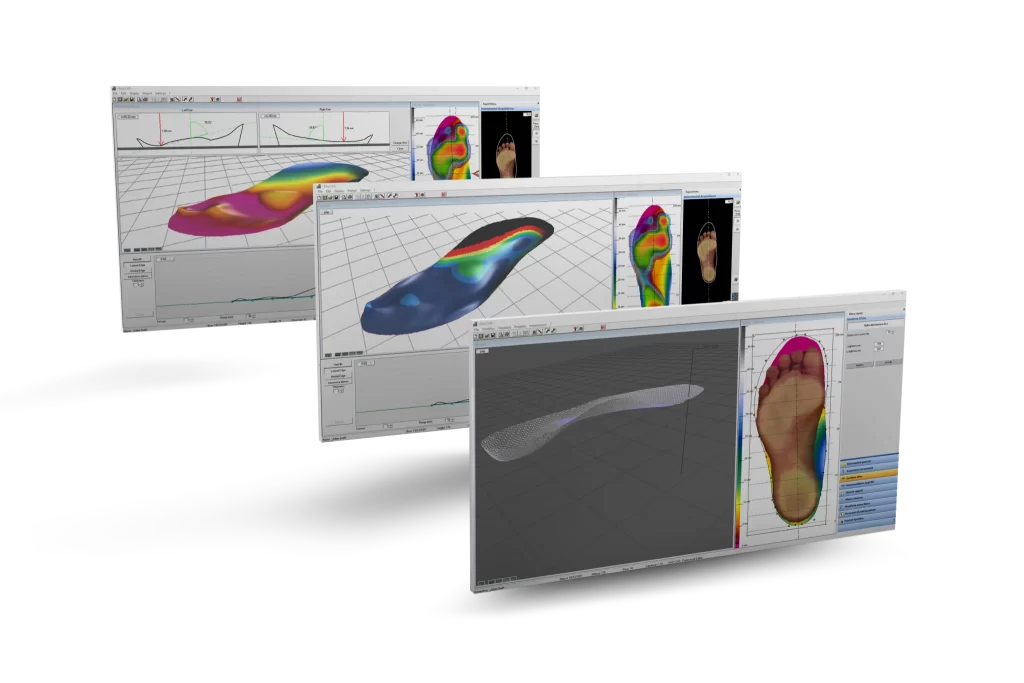

easyCAD, software for making orthotic insoles

Technical specifications

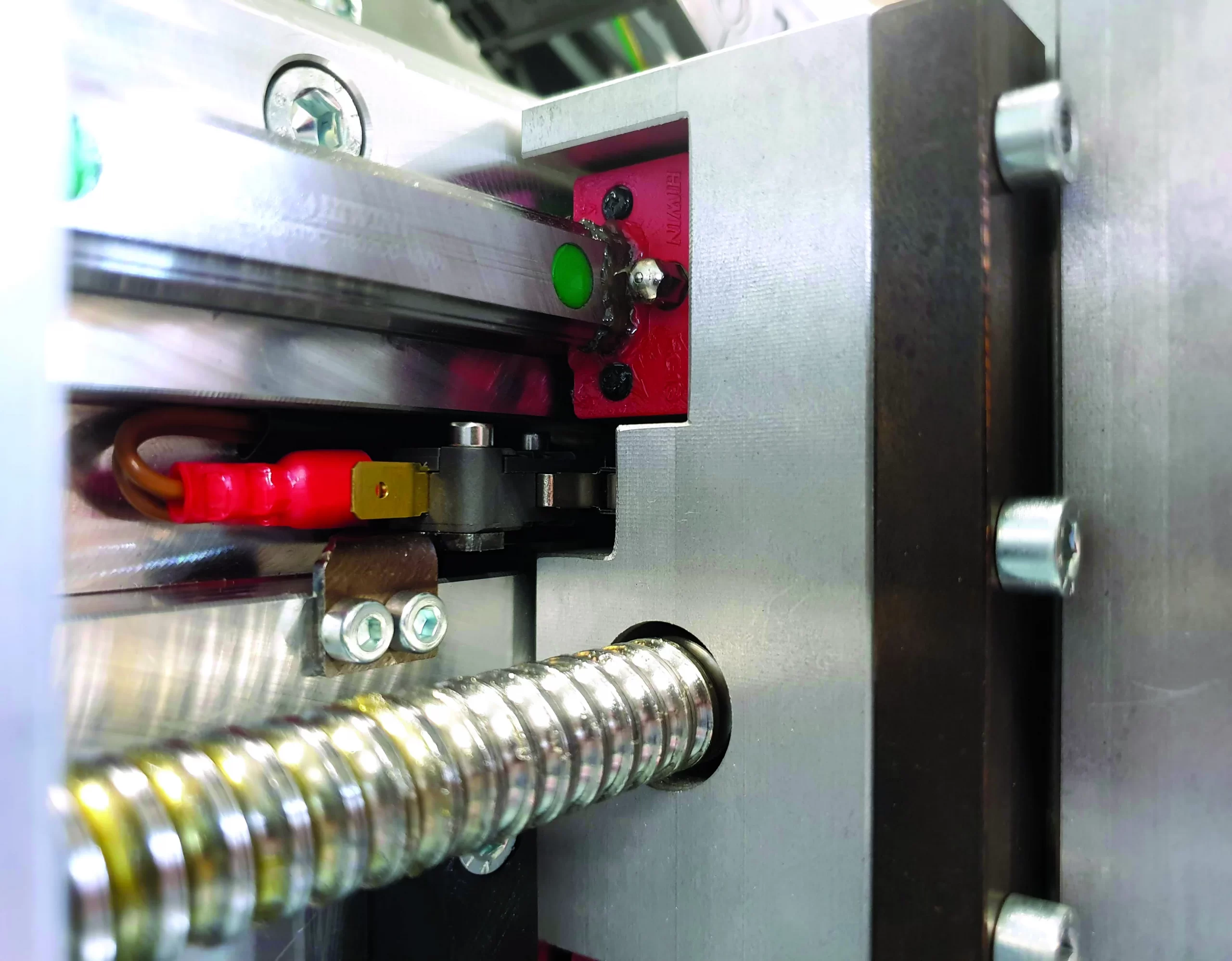

-

3-axis cutter models VX1 and VX1R, dimensions 82x91x104 cm

-

4-axis cutter with independent double Z model TWINCAM 82x111x107 cm

-

Work area: 300X400x80 mm

-

220V single-phase power supply

-

Ethernet connection

Features

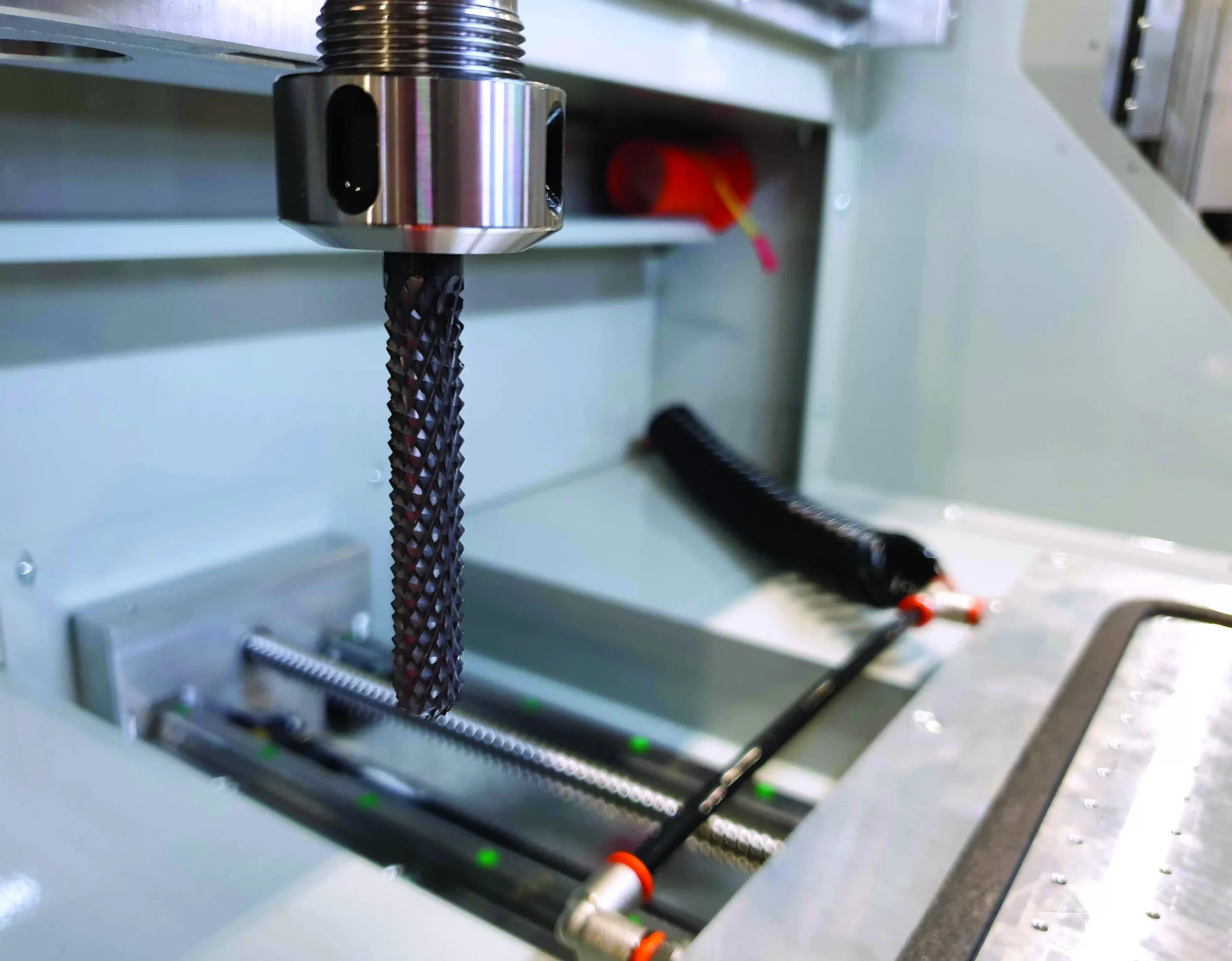

- Brushless motors with machining accuracy up to 0.05 mm

- Machining speed up to 250 mm / sec with acceleration up to 2800 mm / sec2

- Asynchronous motor spindle 24000 rpm,

- Controlled aspirator, for the aspiration of dust and processing residues

- Vacuum pump for sealing blocks without double-sided adhesive

- Pair milling cutter on plates, modules and shaped blanks of different formats

- Milling of polyurethane molds for manual thermoforming of insoles